WE CREATE HIGH QUALITYPRODUCTS FOR OUR CUSTOMERS

We are a premier manufacturer specializing in high-quality gloves for sports, safety, and fashion, crafted from authentic leather, high-grade synthetic materials, and textiles.

We are a premier manufacturer specializing in high-quality gloves for sports, safety, and fashion, crafted from authentic leather, high-grade synthetic materials, and textiles.

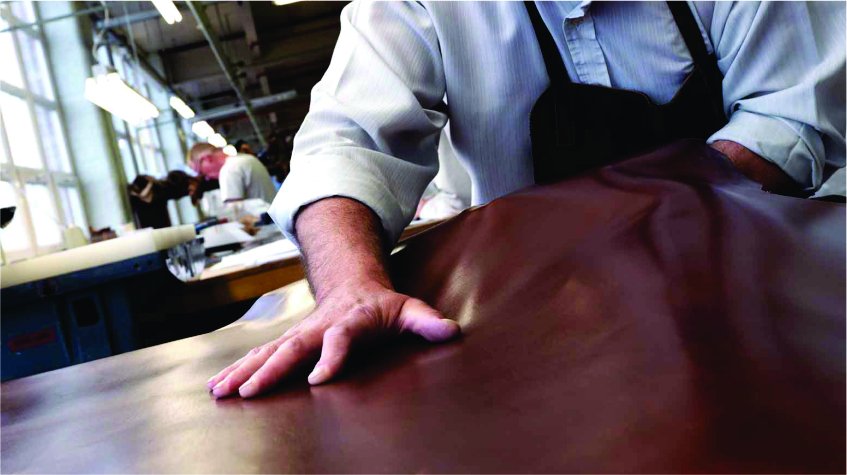

Choosing the appropriate material based on the type of glove being manufactured. Common materials include leather, latex, nitrile, vinyl, and various fabrics. Each material has its own properties and suitability for different applications.

Creating patterns based on the glove design and specifications. This involves drafting templates that define the shape and size of the gloves. Precision in pattern design is crucial for ensuring a good fit and optimal performance.

Using the patterns to cut the selected material into glove pieces. This can be done manually or with automated cutting machines. Accuracy in cutting is vital to minimize waste and ensure consistency.

Stitching the cut pieces together to form the glove. This step requires skilled labor and specialized sewing machines. Depending on the type of glove, different stitching techniques (e.g., flatlock, overlock) may be used.

Applying coatings or treatments to enhance the glove's properties, such as adding grip, waterproofing, or chemical resistance. This step is more common for safety and industrial gloves.

Inspecting the gloves for defects or inconsistencies. This step involves checking for proper stitching, material integrity, and overall quality. Gloves that do not meet the standards are rejected or reworked.

Packaging the finished gloves according to the client's requirements. This could involve packing in pairs, sealing in protective bags, or boxing for shipment. Proper packaging ensures the gloves remain in good condition until they reach the end user.

Shipping the packaged gloves to distributors, retailers, or directly to clients. This step involves logistics planning to ensure timely and safe delivery.